The 1st Hydrogen Dilemma – Storage & Transportation

There are two dilemmas that have been posing delays in the hydrogen economy and therefore decarbonization, the 1st is Storage & Transportation, and the 2nd is the reliable and sufficiently powered hydrogen prime movers.

Storage & Transport of Hydrogen

Most hydrogen is stored either at high pressure, up to 900 bar, or liquified.

Both these technologies call for huge quantities of energy expenditure, as well as actual engineering problems, related to extreme pressures (up to 900 bar), and extremely low temperatures (-256ºC almost absolute “0”).

Weight: ~800 kg

Weight: ~800 kg

Area:1.12 m2

Height:1.80 m

Volume: 2.016 m3

Bundle capacity:

12 Cylinders x 50 l @ 200 bar 120 m3 359 kWh

kWh/ton: 448.8

kWh/m3: 178.1

20 Ft container,

20 Ft container,

Total volume bundle: 27.84 m3

Weight: 33,02 ton

Pressure: 200 bar

Energy contained 16 704 kWh

kWh/ton: 506.0

kWh/m3: 600.0

LOHC Cistern truck with volume: 43 m3,

LOHC Cistern truck with volume: 43 m3,

Weight: ~43 ton

Hydrogen carrying capacity: 2683.3 kg

Energy stored: 89 431 kWh

kWh/ton: 2079.8

kWh/m3: 2079.8

High-pressure hydrogen tube bundles pose the following main problems: Weight, Volume required for storage, Low ratio kWh/ton, Low ratio/ kWh/m3, non-conformable, logistics, high pressure, difficult handling, high pressure standards.

While expensive, dangerous, and inefficient high pressure and liquefaction remain the most common viable solution to date.

To solve the above-mentioned problems, TecnoVeritas is researching and carrying extremely promising tests to overcome those challenges, by introducing Liquid Organic Hydrogen Carriers (LOHC) to the marine and shore market to move large quantities of hydrogen at ambient pressure and temperature and safely, in a virtually non-flammable medium. In fact, it is designing the whole hydrogen propulsion plant for a luxury river cruise ship for Mystic / Douro Azul, which will be the first passenger hydrogen fuelled vessel.

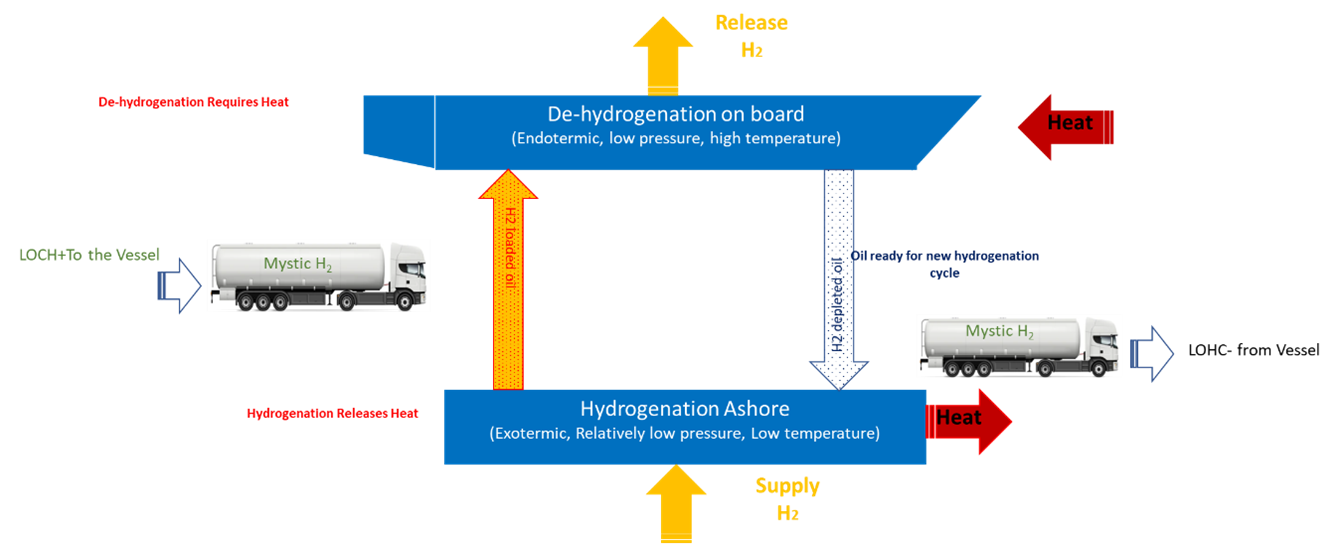

LOHC has an immense edge on pressurized and liquified containers – it is safe to handle and can be moved at room temperature and at atmospheric pressure, and its hydrogenation is an exothermic process, while the de-hydrogenation is an endothermic process that is supplied by the internal combustion engines exhausts heat.

It can also make use of much existing infrastructure designed for liquid fossil fuels, simplifying implementation. This means hydrogen transportation and bunkering can be accomplished by existing transportation infrastructures, for example by barge or truck.

This technology is at pre-industrial testing – so far, allowing the transportation of 58.0 kg of Hydrogen into 1000 litres of LOCH (being a chemical limit 6.2 % m/m).

TecnoVeritas the pre-industrial Hydrogenation / De-Hydrogenation prototypes in operation by end of June 2023.

Next communication, will be addressing the 2nd dilemma, the conversion of hydrogen energy into mechanical or electric energy by using a dual fuel hydrogen engine.