TecnoVeritas Solution for Hydrogen as a Marine Fuel

Despite the lack of Rules and regulations dedicated to hydrogen use on board as a fuel, TecnoVeritas is pushing forward the only effective solution to the decarbonization of the marine industry economically and timely feasible, by using hydrogen safely onboard as a marine fuel.

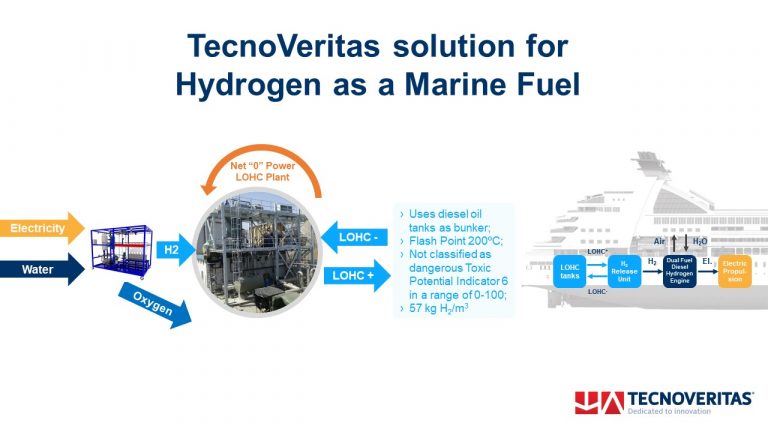

TecnoVeritas hydrogen developments include the design and delivery of the whole required hydrogen chain. Namely the design of the alkaline electrolyser, the safe storage and transportation of hydrogen and the conversion of most existing Diesel engines to Dual-fuel operation (hydrogen with pilot Diesel).

Why is this the solution?

The number of existing Diesel engines in the marine industry is immense therefore if decarbonisation is required, it is not that easy.

Fuel Cells, do not have yet the power/capacity, reliability and cost to become a marine solution for most marine applications, in particular when vessels need to have a reliable prime mover, with high power and reliability. A small, feeder container vessel (900 TEU) has installed a main engine typically of 6 MW power. There are not available in the market such high-power fuel cells, nor the reliability of the existing ones is compatible with a sea-going vessel operation.

Also, fuel cells need high purity hydrogen, typically 25% more expensive than the hydrogen existing engines can burn. Fuel Cell cost and maintenance are also important aspects to consider for the viability of seagoing vessels.

Liquid or high-pressure hydrogen storage and transportation, have several concerns, that need to be addressed wisely, namely involved risks, and involved carbon footprint.

Figure 1 – Converted to Dual Fuel Marine Diesel Engines 9L WARTSILA 32 D

Diesel engines can be operated, with an increased efficiency in a Dual-Fuel mode, i.e., using MDO as a pilot fuel, and hydrogen of regular quality to provide most of the required energy. Conversion rates can reach 80% (and even more in some cases) of the required energy based on hydrogen, therefore accounting for a reduction of 80% in CO2 emissions (provided the hydrogen is green, i.e., produced using renewable energy).

The storage and transportation of hydrogen are based on a Liquid Hydrogen Carrier (LOHC), that minimises the carbon footprint in transportation, as no compression energy waste is almost inexistent, but the main advantage is the utilization of all the conventional fuel systems onboard, and the re-utilization of the carrier for many times after being depleted of hydrogen.