Existing Vessels Revamping to TIER III

While deterioration of earth’s environment is becoming an international problem, reduction of NOx (nitrogen oxides) and SOx (sulphur oxides), PM (Particulate matter / black carbon), and other emissions from ships are being enforced, most of the reduction technologies are easy to implement on new ships, but how about on existing ships?

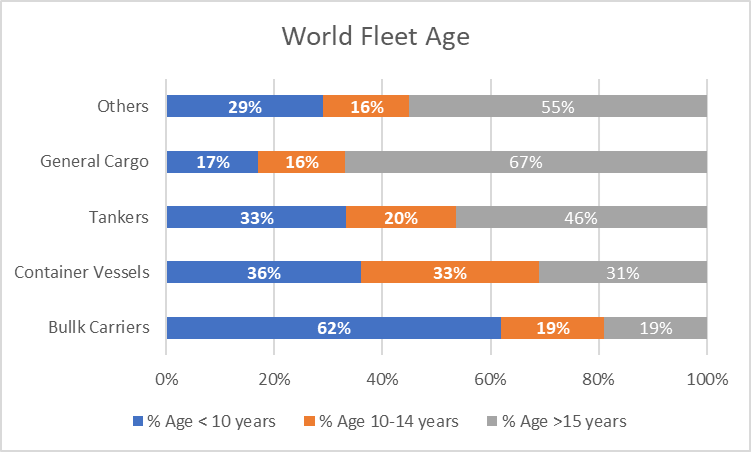

The existing world fleet is not new, but it is not that old to scrap, and therefore needs to be updated in terms of emissions control and energy efficiency.

TecnoVeritas has been conducting in daily basis research and development on how to make existing ships eco-friendly and compliant with MARPOL Annex VI (NOx, EEXI and CII), which regulates atmospheric pollution and energy efficiency ships.

Our Research and Development activities embrace, SCR technology initiated back in 2004, Hydrogen used as a fuel for internal combustion engines, Heavy Fuel Oil desulphurization and Digitalisation of ships operations.

M/V “Vasco Da Gama” one of our environmentally updated vessels,

M/V “Vasco Da Gama” one of our environmentally updated vessels,

2021 at the Heritage Fjords in Norway.

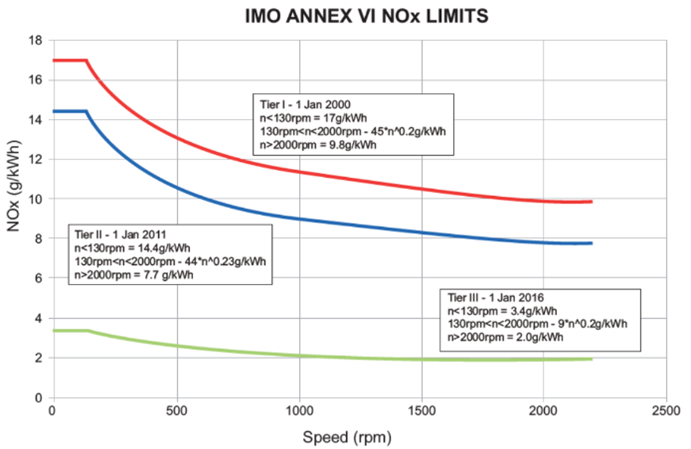

TIER III

Tier III regulations apply when any ship’s keel-laying date is after January 1, 2016 navigates an ECA (Emission Control Area) within 200 nautical miles of North America, Canada and the Caribbean Sea. In addition, after January 1, 2021 this regulation will extend to include the ECAs in the North Sea and the Baltic Sea.

Tier III regulations require a further 80% NOx reduction compared to Tier I, a difficult task for the engine alone and so after-treatment equipment is necessary.

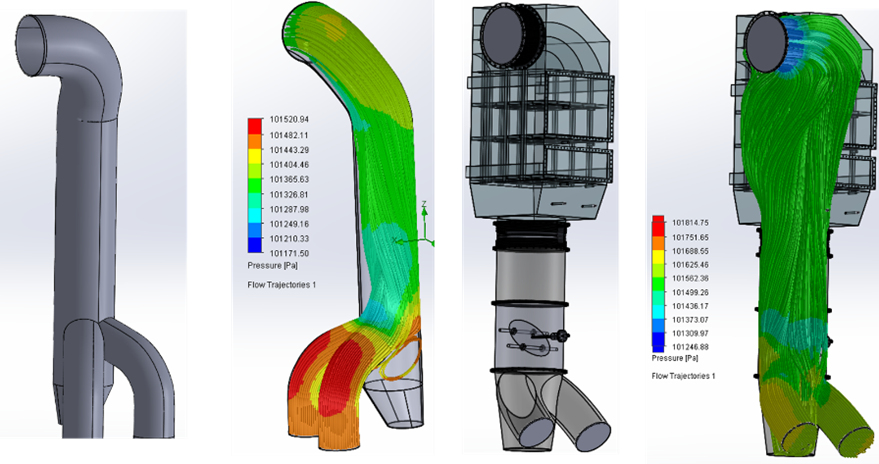

For this reason, we at TecnoVeritas have developed engineering solutions supported by highly advanced tools and techniques that allow customised Selective Catalytic Reduction (SCR) technology to be deployed onboard existing (and new) vessels. TecnoVeritas Clean Technologies has an interesting portfolio of projects, of environmentally updated passenger vessels, that visit the best tourist touristic environmentally sensitive ports, like the Norwegian.

Heritage Fjords, or Antarctica. The vessels’ environmentally updated became as green as new vessels and won a considerable new life expectancy and value.

Exhaust gas piping, pressure loss optimisation with SCR.

(Left original pipework, right optimised pipework with SCR fitted, Sulzer 12 ZAV40S)

The resulting engine-SCR arrangement has proven Tier III compliance. NOx testing takes place on board and in our factory witnessed by the main classification societies.

TecnoVeritas, performs these projects as “turnkey” projects, dealing not only with all engineering feasibility, implementation project, and hardware customisation but also project submissions to Classification Societies and Maritime Authorities. Projects have been done with different engine brands, and Tier III compliance has been achieved and confirmed by independent accredited emissions laboratories.

To optimise the urea consumption, TecnoVeritas SCR’s systems have a closed loop control system, that receives information from each engine stack NOx, SOx, and CO2 Sensors also MARPOL VI compliant.

A comprehensive emissions monitoring system is also included to monitor, exhaust emissions, either onboard or remotely.

It is important to note that all the components of the systems are Type Approved are stamped with ID numbers indicating they conform to the regulations. These numbers are entered on the NOx Technical File of the engines, or the NOx File (for ships with the keel laid before 2000).

Also, the vessels can receive a new class notation, ECS (SCR) for example if the vessel is LR classed.

If you are considering how to comply with the above regulations for your existing fleet or new builds, please contact us and we will be happy to explain the various technologies and support available to you.