A New Patent from TecnoVeritas that can compete with Scrubbers

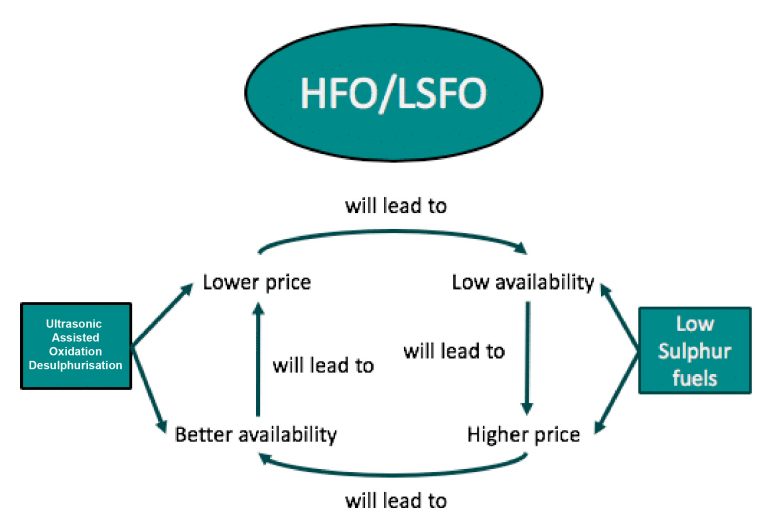

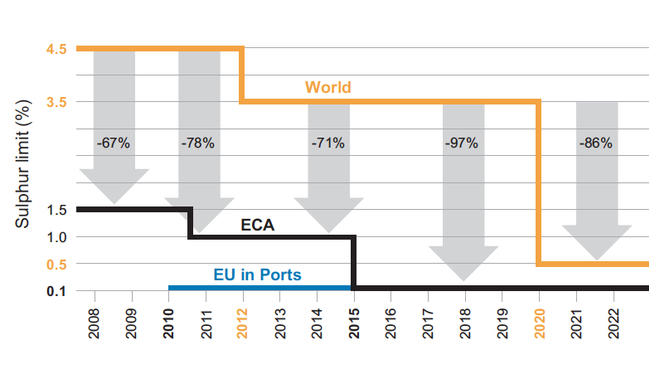

The process is dedicated to the reduction of sulphur content of Heavy Fuel Oils (marine and power plant bunker fuels), based on the Oxidation of sulphur with the assistance of Ultrasounds, known as Ultrasonic Assisted Oxidation Desulphurisation.

The main advantages are the mild conditions of the process when compared with the common hydro-desulphurisation i.e., no use of hydrogen at high temperature and pressure, very low energy consumption, inline stream processing production, and relatively small plants.

The process was developed based on the observed reduction of sulphur reduction during emissions tests for the performance of Enermulsion, another ultrasonic based equipment for the control of emissions (NOx, CO, PM and Consumption) in power plants, and Cogeneration plants (using marine diesel generators, and boilers). Enermulsion has also used Slop oils valorisation, at IMO Slop Oil plants, receiving such products from ships.

1 comments on “A New Patent from TecnoVeritas that can compete with Scrubbers”

Would love to know more about this process.