Two Stroke Cylinder Liner Monitoring System

Back in 2010, TecnoVeritas led a Research to develop a system for detecting the faulty running conditions of two-stroke marine Diesel engines, which resulted in a European Patent owned by TecnoVeritas is based on: “Monitoring and Detection System for Scuffing Between Pistons and Liners in Reciprocating Machinery”.

The system is dedicated to the detection of faulty running conditions of liners of two-stroke marine engines at a very early stage (it can be adapted to other reciprocating machinery), therefore warning for such faulty running conditions before failure occurs.

The system would avoid engines having extremely costly damages, and ship safety problems.

It is based on the use of inductive transducers, cylinder pressure sensors, and others, that feed data into a mathematical model of engine liner piston interaction. A real-time drain oil analysis is also associated, so that forecast of liner condition is possible, therefore increasing the confidence on the decision of maintenance decisions.

The system was installed in an RTA SULZER engine, for real operational conditions monitoring.

Figure 1 – Sensor cabling entering the scavenging air trunk.

Figure 2 – Local sensing signals cabinet.

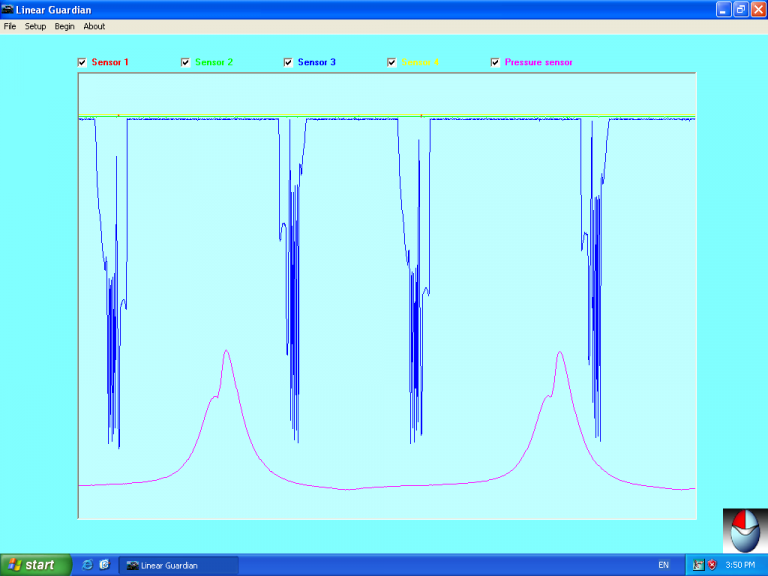

Figure 3 – Monitoring Software screen, relating cylinder engine pressure with piston rings roughness. Using this interface, alarm limits can be defined.

Figure 4 – Cylinder cock valve instrumented with an online pressure sensor.

The system was used to perform various studies on lube-oil spreadability and multi-grade lube-oils for a major oil company, to determine the oil film thickness after several cycles and engines power, liner temperatures, and lube-oil feed rate. Artificial Intelligence data treatment was successfully used.