ISO 50001 – The New Approach on Energy Management

As a systematic and voluntary way to reduce energy consumption on a company or a process, this norm has been created in order to answer to the growing necessity of enhancing performances and creating efficient processes overall. The application of ISO 50001 to your organization finds energy efficiency solutions and behaviours while saving your money. The essential aspects to ensure while performing the implementation of an Energy Management System (EnMS) are the following:

- Knowledge of the organization’s energy consumption: why/how/where/when energy is consumed, and how much energy is consumed;

- Accounting and monitoring of the evolution of energy consumption;

- Availability of data for decision-making on measures to be taken to improve energy performance;

- Adoption of measures to optimize the use of energy;

- Control of the results of actions and investments made to improve energy performance.

How is it performed?

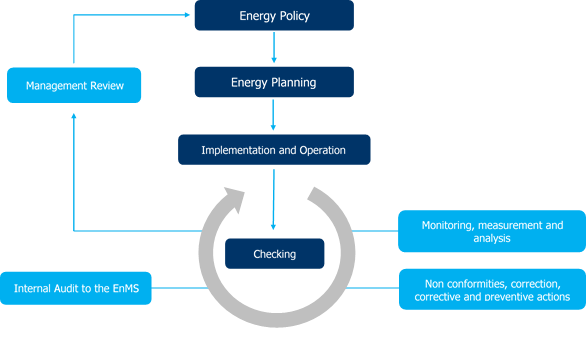

Based on a Plan-Do-Check-Act model, ISO 50001 is applied either to the whole organization and including every collaborator, or simply to a process and its stakeholders, monitoring and improving it continuously:

Plan: carry out the energy assessment and establish the baseline, the indicators of energy performance, goals, targets and action plans necessary to produce results that will improve the energy performance accordance with the organization’s energy policy;

Do: implement energy management action plans, including procedures and processes, with the aim of improving energy performance;

Check: monitor and measure processes and products, key characteristics of operations that allow determining the energy performance in relation to energy policy and goals, and report the results;

Act: take actions that aim at continuously improving the performance of the EnMS in relation to the results achieved.

Figure 1 – Plan-Do-Check-Act (PDCA) Methodology

Applicable to organizations of any size, it is expected that this norm can affect up to 60% of energy usage at a global scale, by assessing the present status of the organizations and promoting better energy usage methods. Being a continuous approach in time, it is expected that all the organization is involved, having continuous training and information to the greater good of the process.

The solutions found and applied are also monitored in order to assess the achieved outcomes resulting from the established objectives, and to know if these are being successful and how can they be improved. The constant monitoring results on continuous and longstanding results.

Depending on the depth of the analysis and of the size of the organization/process to be included in the application of the norm, it is expected that the process takes from 1 up to 3 years to be concluded and running.

The Steps

Step 1 | Initiate the implementation of an EnMS according to ISO 50001

Perform an initial revision to the EnMS (Gap Analysis).

Step 2 | Top Management Commitment

The implementation of the energy management system should begin with the commitment of the top management, which should ensure the availability of all the resources needed for its implementation and for the improvement of energy performance.

- Perform the energy assessment to the organization;

- Defining the reference energy consumption;

- Define energy performance indicators.

- The fundamental role of human resources;

- Define internal and external communication strategies;

- Ensuring documentary control and operational control;

- Integrate energy criteria in the design of installations, processes or products;

- Integrate energy criteria in the acquisition of energy, services, products and equipment.

- Ensure the monitoring, measurement and analysis of the key characteristics;

- Assess compliance with legal requirements and other requirements;

- Define the internal audit plan for the EnMS;

- Manage nonconformities, corrections, corrective and preventive actions;

- Define the form of control of the internal records of the EnMS.

Advantages

- Reduce Energy consumption;

- Increase productivity;

- Escalation of competition power;

- An enhanced and deeper knowledge of your organization/process;

- Improved costs planning.

Disadvantages

- Planning involved in a power management system is complex and time-consuming;

- Control of costs arising from the implementation of the management requires particular attention by the management of the top.

As a 25-year-old company, Tecnoveritas has just the necessary experience and know-how to help you implement ISO 50001 on your organization while making a complete energy survey that will grant you full knowledge of the efficiency of your business.